About Us

Club Contacts

Junior Shooters

Upcoming Activities

Recent Activities

Member Ramblings

Books and More

Range Rules

Range Schedules

Useful Links

Website Policy

New Ontario Shooters Association (NOSA)

Nolalu Shooting Range Development

NOSA has been fortunate to have full use of the magnificent outdoor Nolalu Shooting Range for 4 days each week from May through October. [We now shoot indoors at the Thunder Bay District Fish and Game Ranges.]

The Nolalu Range was originally called the JR Range before being given into the capable care of our own Wade W. And wherever possible, NOSA has attempted to help Wade improve the portion we use for outdoor club activities.

This summary page is intended to describe and show some of our NOSA members' activities, while working to develop the Nolalu Shooting Range over the years.

The Nolalu range work photos and details from individual years (starting with 2010) can also be seen on their respective year's Recent Activities webpage (accessed through the Recent Activities link at left).

Click on the individual images here to see a larger view.

NOSA Nolalu Shooting Range Improvement Projects in 2009

The 2009 year's new provincial range standards found a need to build up the backstops on both Ranges #1 and #2 to monumental heights. Unfortunately the volunteers forgot to take along a camera to record the work in progress. There is an old saying that: "If there ain't a picture, it never happened." Well actually we do know it happened because the backstops now block out a much bigger chunk of sky.

Another improvement for safety was the construction of a massive wood baffle on Range #2 in front of the two benches provided for shooting at 300 metre targets. When seated at these two benches, you naturally have to point the barrel under the baffle to see or to hit 300 metre targets.

Shooting Range Flags. These Juniors are demonstrating how members shall ensure the correct flag is erected for the particular shooting range being used. The GREEN FLAG indicates a safe range with no shooting taking place. The RED FLAG here indicates that this particular range is being used for shooting. (More information about range and club rules can be found on the Range Rules page at left, along with a map to the range.)

NOSA Nolalu Shooting Range Improvement Projects in 2010

In this section we list projects and activities relating to our industrious members, working to improve the Nolalu outdoor shooting range facilities for the 2010 year. Details kindly provided by Terry D. Scribed by S.B. aka Banacek.

25 April. A most happy gang went to Nolalu to deliver materials and work (paint/dig/hammer/bolt/joke/sweat/laugh) alongside Terry D. who is our Properties Chairperson. Volunteers included: Dana C., Dan G., Don K., Ricky B., Trapper-John A., Wade W., and Warren W. The existing fence got straightened along with the old gate. A new second gate (same new club lock on both) was installed and lots of paint was used to make everything spiffy. Trapper-John certainly loves his red paint. The range baffle was stabilized with heavy wire guys for safety. Our particular thanks go to Hugh Paxton (Wire Rope Industries Ltd.) and George Hill (George Hill Supplies Ltd.) for providing sound advice and generously sharpening their pencils on materials needed.

May. A big thanks to member Scott B. who is generously making available some heavy material for integration into the stabilized flooring design at the firing points.

20 June. This last day of spring was unusually hot and sunny and found an intrepid band at the range sweating for several hours as they prepared the pistol range firing point area for new surfacing. At this time they moved the benches and then wrestled a very heavy tarp material into submission. The tarp will be covered with compacted crusher stone in the near future. Volunteers working with Terry included: Andrew, Dana, Jason, Peter and son, Trapper-John, and Vern. Thanks guys.

30 June -- More Pistol Range Improvement. Our website on the Recent Activities page has reported ongoing work this year at Nolalu to improve the range. This next step was a work party to improve the ground around the firing point.

--- Our landlord and fine member Wade W. phoned our range rep Terry D. to say he had just arranged a truck and loader and 100 metric tonnes of fine gravel were being delivered. So these two valiant members along with Wayne H. proceeded to the pistol range and had at it. Yes they had a loader for part of the work, but there was still an awful lot of back-breaking manual shovel work spreading and packing.

--- In the table below we start with Terry's three photos, of one 25 tonne truckload being dumped, Wayne and Wade using loader and shovel (yes, Terry put down the camera and wielded a shovel too), and the pistol range about 3/4 finished. Looking good.

--- So a VERY BIG THANK YOU to Wade W. and Terry D. and Wayne H. for a job very well done!

Some comments from Terry afterwards: "The 29th of June I went to the Conmee pit to actually see what we were going to get for product, and arranged with truck drivers to dump the 1st load around 9:30 a.m., June 30th, before rain set in. Dump truck round trips were 1 1/2 to 2 hrs between truckload dumps (4 of them).

--- I wanted to build up a pad in front of the sign-in box as well, and we did so -- for brass and burning barrel as well. Wade was also going to replace the old barrel with a new one.

--- The finished pistol range is smoothed out to both sides all the way down to the end. Wade W. brought a packer and painstakingly went over the whole area. Wayne H. even assisted by doing a lot of raking, in addition to spreading most of the material with the loader.

--- The material provides an excellent packed surface and pretty much becomes solid after walking away from it. We got the surface as smooth as possible for the added material which was anywhere from 6 inches to over 1 foot thick. Tarps were good but occasionally gathered as 25 tonnes of load plus truck ran over them.

--- No notification to others went out because I checked with the weather forecast and it was grim for July 1st, so I got truckers to haul Wednesday June 30th. Wade arranged for Wayne to be there with a loader for 9:30 - 10:00 a.m. Extra gravel was spread to prevent the truck from getting stuck more than it did. You can imagine what a little extra rain would have done to that!"

08 August -- Meeting in Thunder Bay with Supervisor of Clubs and Ranges, Chief Firearms Office Ontario. Sgt Peter N. and his new Range Inspector Rick G. gave a briefing to representatives of the local gun clubs including NOSA. Some highlights include:

-- Section 24 of the Firearms Act governs Ontario's 207 clubs with 239 ranges plus 32 private ranges.

-- The normal range inspection schedule is once every two years and is on track.

-- Peter provided an interesting overview of the GPS system now used to survey ranges and ensure safety in the arcs of fire.

-- Where any problems are found, the CFO works with the range owner to find practical solutions to meet the needs of public safety.

14 August -- Day One. Terry D. arranged to get Robert N. and his Bobcat out to the range on this sweltering hot day. What turned out to be a successful two-day operation was all necessarily on very short notice. Timing for Day One depended on the availability of the heavy equipment needed.

--- Then the amount of progress on Day One dictated whether and when Day Two could happen. (There might have been a delay if large rocks got in the way.)

--- Terry and Banacek and Wade W. assisted with shovels and cheers and buckets of sweat equity.

--- Robert drilled eight holes over 6 feet deep at the firing point for Range #2. He then changed accessories for a bucket to further level the gravel recently used to surface the pistol range (Range #1).

--- Some seemingly very long and scorching hours were spent on site. Banacek's pix are in the table below. Vultures circled ever closer ;-)

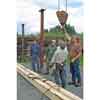

15 August -- Day Two. The night before, Terry D. had borrowed a massive boom truck and loaded it with 8 very heavy lengths of pipe up to 28 feet long. In the very early (for a Sunday) morning his son Jerry and Banacek convoyed with him to the range and were met there by Glenn H. and Wade W.

--- The weather was much cooler and perfect for the labour this day. Still lots of sweat but no heat stroke.

--- Every phase of this operation had physical risk but Terry first stabilized the truck and then skillfully operated the boom, and directed all operations to keep us safe.

--- Glenn was not fishing for groundhogs; he was lowering footing steel plates into yesterday's holes.

--- Banacek took the pictures and worked too. (Thanks Terry for using my camera to take a picture to prove I was there.)

--- The base of each pole was first wrapped with heavy but loose plastic to prevent frost heaving. (The holes were below normal frost levels but the plastic ensured pole stability -- far better than concrete collars that would heave.)

--- Each pole was lifted and guided into position, and then lowered and coaxed into alignment; the hole was filled and firmly tamped. Final vertical alignment will take place when more upper structure is added before the roof goes on.

--- More Banacek pix are below, including triumphant Terry standing within our masterpiece, Ironhenge.

--- An amazingly good time was had by all.

NOSA Aerial Photos at Nolalu Range -- Sunday, 10 Oct 2010

While all the ranges were green, Banacek took some aerial pictures on this lovely fall afternoon. (Technical details can be seen in the Member Ramblings section in the article "Behind the Scenes at NOSA's Website".)

NOSA Nolalu Shooting Range Improvement Projects in 2011

Our shooting benches on Range #2 for the 100m and 200m targets have sprouted some simulated antlers thanks to Roy R. who has been busy in his workshop. The intent here is a reminder to shooters seated at these benches, to always keep their barrels low and near horizontal, and never pointed above the cross-bar. (Firing at targets can also be done on the ground from the standing or kneeling or sitting or prone positions, which provide better practice for actual hunting situations, or for some matches in target competitions.)

In 2010 Terry and a band of volunteers erected Ironhenge at our Nolalu range. Planned development for 2011 was slated for a low cost stage, namely putting frost-antilift collars made of foam around the base of each pole, and then covering and levelling the firing point area with crusher run gravel.

August 23 this year found a couple of the lads playing with giant gravel castles. Dana C. kicked the castles down in a cloud of dust, and then raked while a Bobcat got to play too. Photos (and a very tiny bit of the work ;-) by Terry D.

|

|

|

|

|

|

NOSA Nolalu Shooting Range Improvement Projects in 2013

Our Range #2 roof project, which started in 2010, finally acquired enough funding to be comfortably continued this year. The earlier work can be seen on the respective activities pages for 2010 and 2011. What happened in 2012? No big construction, but we added a couple more firearms stands for club events.

Tuesday, 16 July 2013

A few of the usual suspects (NOSA folks who volunteer for everything) turned up at the range about 9 a.m. to cut the roof support poles to final length, and insert the massive steel beam supports that had been welded up by Kevin K. Volunteers included: Dana C., Terry D., Don K., Don M., Larry P., Warren W. and yours truly, Steve B., who also took the pix here. What a wild bunch; it was much like herding cats and with more opinions present than found at the U.N.

Tuesday was the only day early this week that was originally forecast to be rain-free. We still had a twenty minute shower that was actually pleasant, during what was to become the scorching hottest day so far this year. Afterward we adjourned into St. Urho's for a late lunch and well deserved rest in the shade.

Click on the individual images here to see a larger view.

Monday, 29 July 2013

Monday turned out to be everything we hoped for in a fine sunny summer day. [Those are exceedingly rare of late.]

Our work party began at the Nolalu Range at 9 a.m. and we were soon hard at work nailing together the two massive main beams for the roof structure.

On hand were most of the usual suspects (members that have not yet learned how to hide from the press-gang): Eugene B., Keith C., Dana C., Terry D., John Gi., Don K., Bob M., John Sa., Susan C. and Wes W., and yours truly Steve B. who also took some pix.

Susan asked whether I was going to get a picture of her working; that was not a problem, and not posed, as she hammered all day with the best of them.

After toiling in the sun, folks retired to the sanctuary of St Urho's for a well deserved late lunch and congenial conversation.

Wes and Susan kindly regaled us with stories from his and Susan's recent bow hunt in Australia, and his successful walrus hunt last week. Fascinating stuff that I wish we could persuade him to write up for his biography. Lots of incredible facts we never knew, and all rolled into some very exciting true tales.

Click on the individual images here to see a larger view.

Tuesday, 30 July 2013

Tuesday morning found exactly the same group of 11 hard-working volunteers that had turned out on Monday.

With us for the morning were Eugene B., Keith C., Bob M., and Susan C. & Wes W.; their continued efforts were very much appreciated.

With us for the whole day from 9 to nearly 5, with no break for lunch, were Dana C., Terry D., John Gi., Don K., John Sa. and Steve B., who also took more pix.

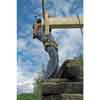

This session we used a huge boom truck provided by Terry to lift the massive beams into place, whereupon the poles were tweaked straighter with come-alongs and Don's truck before we lagged the brackets to the beams. Dana then welded the brackets to the poles, and all pitched in to help Dana weld inter-pole bracing all around. Using the boom truck, groups of 24 foot long rafters were hoisted onto the structure, ready for the next stage.

What is not obvious from the pictures are the many small steps involved of taking measurements and making calculations and lots of lifting and moving stuff and scrambling up and down ladders and scaffolding. Busy!

For those who have not seen it, Dana has a home-made portable welder that had its origin with an antique Wisconsin engine taken off who knows what. As a kid Dana used it to power a go-cart when he was about 10 and it is so worn now that there is very little piston left above its ring. Nevertheless it has spent the last 30 years powering a 24 volt generator off an aircraft to make a truly effective stick welder. The motor ran continually all day without a hiccup. Try that with a modern welder.

Click on the individual images here to see a larger view.

Thursday, 01 August 2013

August 01 found us at the range for the third day this week to work on the roof project.

Volunteer workers included Eugene B., Dana C., Terry D., John Gi., Don K., Dave O., John Sa., Warren W., Wes W., and Steve B. who also took these pix.

The rafters were nailed in position this day and almost all the strapping. Weather rain showers interrupted the work for short periods but were refreshing. Eugene B. and John S. also made four new target frames for Range #1 and one for the 200M range. Eugene also trimmed back a lot of brush concealing targets on Range #2. We ended up close to 6 p.m., which made it another long day.

We have already ordered the metal roof sheathing, which should arrive within two weeks, at which point we will have our last roofing work party.

One thing has become evident, many instances of wet weather like we experienced this summer would have been a lot easier to tolerate at the range with a waterproof roof overhead. And if it rains during a club event, at least soon we will have a dry area to use the BBQ and avoid soggy hamburger buns.

A gentle reminder that when putting up your targets, please fasten them well inside the framed area so that most bullet strikes will miss the actual wood frames. The plastic covering is easy to replace, but the wood frames take a fair amount of work and expense to replace.

Click on the individual images here to see a larger view.

Thursday, 15 August 2013

Today needed over 10 hours of work -- making and situating one final rafter, putting on fascia boards (pressure-treated and heavy!) and finishing roof strapping; and applying steel tie-downs to the rafters, before finally hoisting the 24.5 foot long steel roof sheets and fastening them down with screws applied along every metal ridge. A very busy time under an uncharacteristically blazing sun and hot day -- rare this summer.

Starting at 08:30 a.m. and working all day were Dana C., Terry D., Glenn H., Don K., John Sa., Wes W., Warren W., and Steve B. who also took some pix. Three other folks were kind enough to come out after their daytime jobs and pitch in to help finish the project: Bob J, Dave V., and Dale Z. Everyone's help this day, and throughout the project, was very much appreciated.

Needless to say, after three years the hardy band of volunteers on this particular range project are very happy it is finally over :-)

Click on the individual images here to see a larger view.

NOSA Nolalu Shooting Range Improvement Projects in 2014

After extensive work in the prior years, 2014 found us in a quieter period. We commend and thank Don M. for his dedication, doing lots of rebuilding of the many target frames, and modifying the baffle used for shooting at 300 metres. After we had added gravel under the shooting tables that raised them several inches, it became difficult to see under the baffle, even when it was adjusted to its highest position. Consequently the bottom of the baffle was trimmed this year for better clearance.

NOSA Nolalu Shooting Range Improvement Projects in 2016

Workparty -- Saturday, 16 July 2016

Terry D., our Properties Chairperson, scheduled some Nolalu range maintenance for this Saturday.

Terry and President Dana C. and Steve B. turned up to help.

Workparty -- Sunday, 21 Aug 2016

Terry D., our Properties Chairperson at that time, completed some Nolalu range work -- mounting all the aluminium roof fascia, with the capable assistance of Dana C., John Gi., and Brian R. Terry took these pix of the work and crew.

Click on the individual images here to see a larger view.

|

|

Maintenance Since 2016

While there has been ongoing routine maintenance, no major projects have been undertaken lately.

Warning and Disclaimer. Only the most current printed Shooting Rules and Range Standing Orders and Match Standing Orders as issued by the N.O.S.A. Executive are official and they should be read, understood, and followed. If there is any question as to interpretation of a rule, or safety of a practice, immediately ask a member of the Executive or a Range Safety Officer before placing yourself or anyone or anything else at risk. Any activity involving firearms has inherent dangers. Some contents on this website may include personal opinions and experiences or practices that should not be emulated. Everyone viewing this website, or any other website or book or magazine or pamphlet or media source, is cautioned to seek professional advice first about anything written or implied or inferred. Your safety is your personal responsibility.

Copyright © 2010 - 2021 New Ontario Shooters Association. This site is copyrighted and no content may be reproduced by any means, including electronic, without written permission except for strictly personal use. Other websites wishing to post a link to this site are welcome to do so.

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)

_th.jpg)